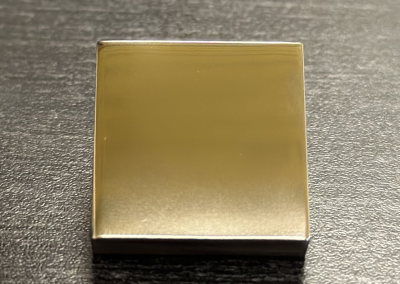

Specialty Coatings

About our Specialty Coatings.

Our PVD is 2800 Hv to 3000 Hv. Teikuro PVD provides a lubricous surface.

Our DLC-Si has a coefficient of friction unmatched by other coatings.

Benefits of T-Forte (PVD):

- Vanadium-based hard multiplayer coating

- Greater Impact Strength

- Excellent Galling Resistance

- Reduces Wear

- Low Temperature Process

- Over 10 µm thickness

- Good Hardness (Approx. 2800 Hv)

Applications for T-Forte (PVD):

- Hot Stamping

- Aluminum Stamping

- Forming Dies

- Draw Dies

- Automotive Stamping Dies

Benefits for K-Forte (PVD):

- Titanium-based hard multiplayer coating

- High Heat Resistance to Friction

- High Impact Strength

- Excellent Galling Resistance

- Reduces Wear

- Approx 10 µm of coating thickness

- Good Hardness (Approx. 3000 Hv)

Applications for K-Forte (PVD):

- HSLA Forming

- Cold Stamping

- Forming Dies

- Heavy Stamping Dies

- Trimming Steels

- Bending Dies

Benefits of DLC-Si:

- Low Friction

- High Wear Resistance

- Great Seizure Resistance

- High Electric Resistance

- High Coating Rate

- Superior Adhesion

Applications for DLC-Si:

- Draw Die (HSLA, Stainless, Aluminum, etc)

- Flange Die

- Bending Die

- Powder Compacting Die

- Cutting Tools (Dry or less lubricant)